Hidrostal Pumps are globally recognised for their unique screw centrifugal impeller design, offering reliable, low-shear pumping of fluids with high solids content. Manufactured by HIDROSTAL — a Swiss-based company with over 60 years of innovation in fluid handling — these pumps are designed to meet the most demanding requirements in municipal, industrial, food, and wastewater applications.

At the heart of Hidrostal Pumps is a patented impeller geometry that combines the efficiency of a centrifugal pump with the solids-handling ability of a positive displacement pump. This design delivers gentle, clog-free performance that protects both the pump and the product being transferred, whether it’s raw sewage, sludge, slurries, or delicate food products.

Hidrostal Pumps are used worldwide in wastewater treatment, flood management, food processing, power generation, and agricultural systems. Their ability to handle fibrous and abrasive materials without compromising flow makes them ideal for situations where reliability and efficiency are non-negotiable.

A key feature of Hidrostal Pumps is their non-clog performance. The large free passage and open channel design minimise the risk of blockages and enable the safe handling of suspended solids and debris. This significantly reduces the need for intervention and keeps systems running smoothly with lower maintenance requirements.

Hidrostal Pumps are also prized for their energy efficiency. Thanks to optimised hydraulics and precision manufacturing, many models outperform traditional submersible or end-suction pumps in real-world operating conditions. Their smooth, low-pulsation flow reduces wear on system components and supports overall process stability.

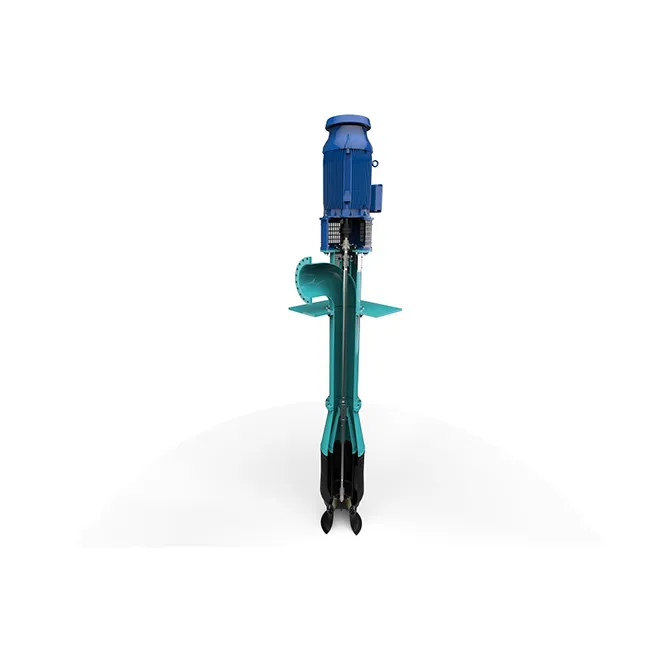

Material options across the Hidrostal range include cast iron, duplex stainless steel, and high-chrome iron, giving engineers the flexibility to specify pumps for aggressive, abrasive, or corrosive fluids. The pumps are available in dry-installed, submersible, or vertical configurations, allowing integration into a wide range of system layouts.

Another advantage of Hidrostal Pumps is their suitability for variable-speed operation. This allows for fine-tuned control over flow rates and system pressure, helping operators optimise performance and reduce energy costs across varying load conditions. Combined with robust bearings, seals and motors, these pumps are built for long service life in continuous duty applications.

The unique impeller geometry also makes Hidrostal Pumps an excellent choice for sensitive media. In food and beverage environments, for example, the pump’s gentle handling ensures that solids such as fruit or meat are not damaged during transfer, making them highly effective for hygienic and delicate processing tasks.

As a UK supplier of Hidrostal Pumps, Tomlinson Hall offers full product support, selection assistance, and aftercare services. Whether you need a reliable pump for stormwater handling or a hygienic solution for a food production line, we can help identify the best-fit model based on your flow, head and fluid characteristics.

In addition to new installations, Hidrostal Pumps are often chosen for system upgrades where reduced downtime and maintenance savings are key priorities. Their dependable performance and ease of integration make them a smart investment for engineers and plant managers seeking long-term value.

To find out how Hidrostal Pumps could improve the performance and reliability of your system, contact the team at Tomlinson Hall. We’re here to support your project with expertise, product availability, and a focus on practical, efficient solutions.