Crane Valves

Crane Valves deliver high-integrity flow control solutions trusted in critical environments worldwide. Built on more than a century of expertise, these valves offer precision, durability, and safety across industries including chemical processing, pharmaceuticals, biotechnology, and refining. When process control must be dependable and compliant, Crane Valves deliver results.

Trusted Solutions for Regulated Industries

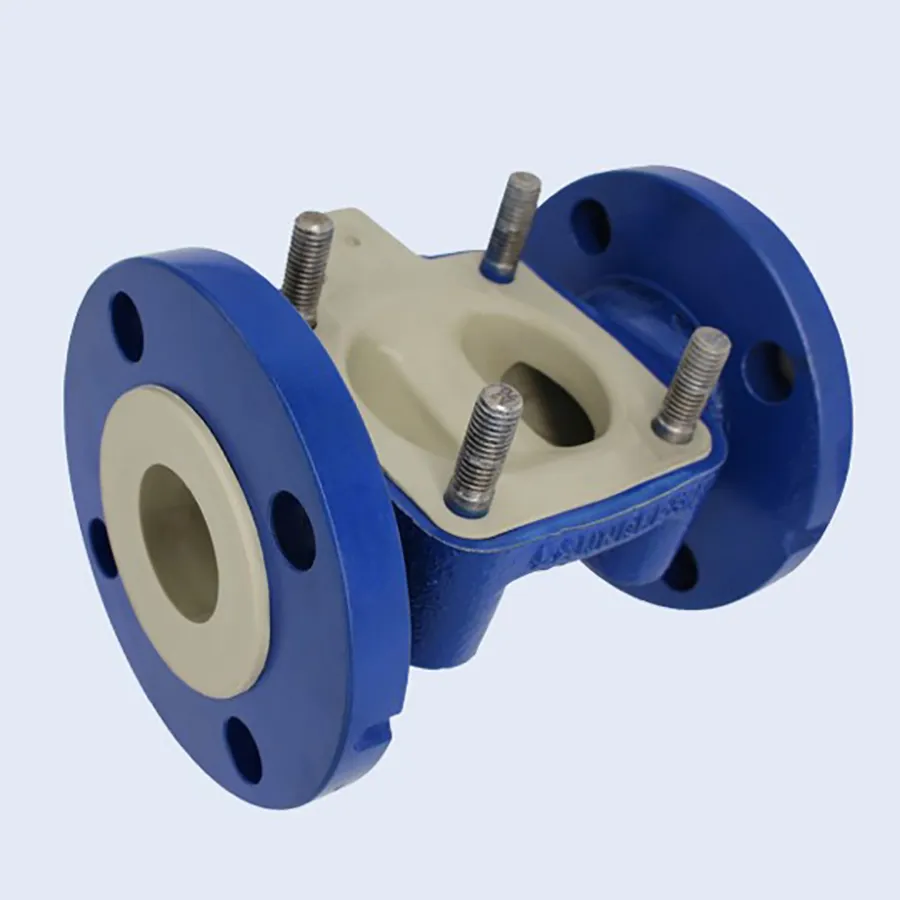

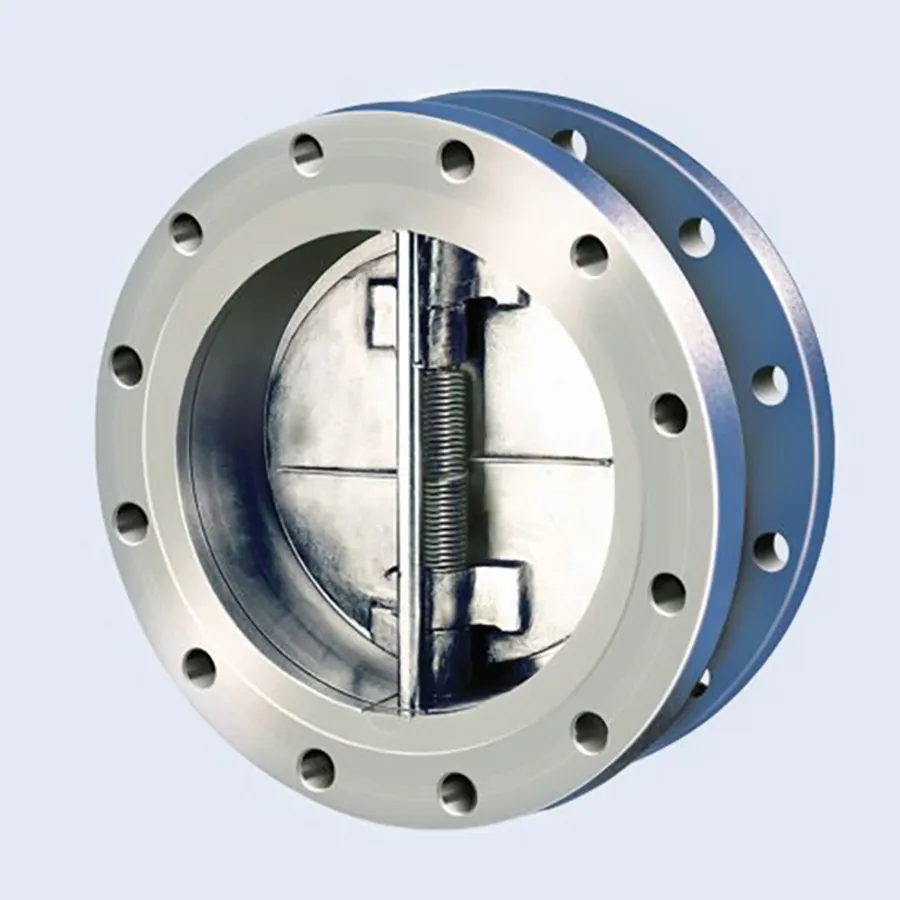

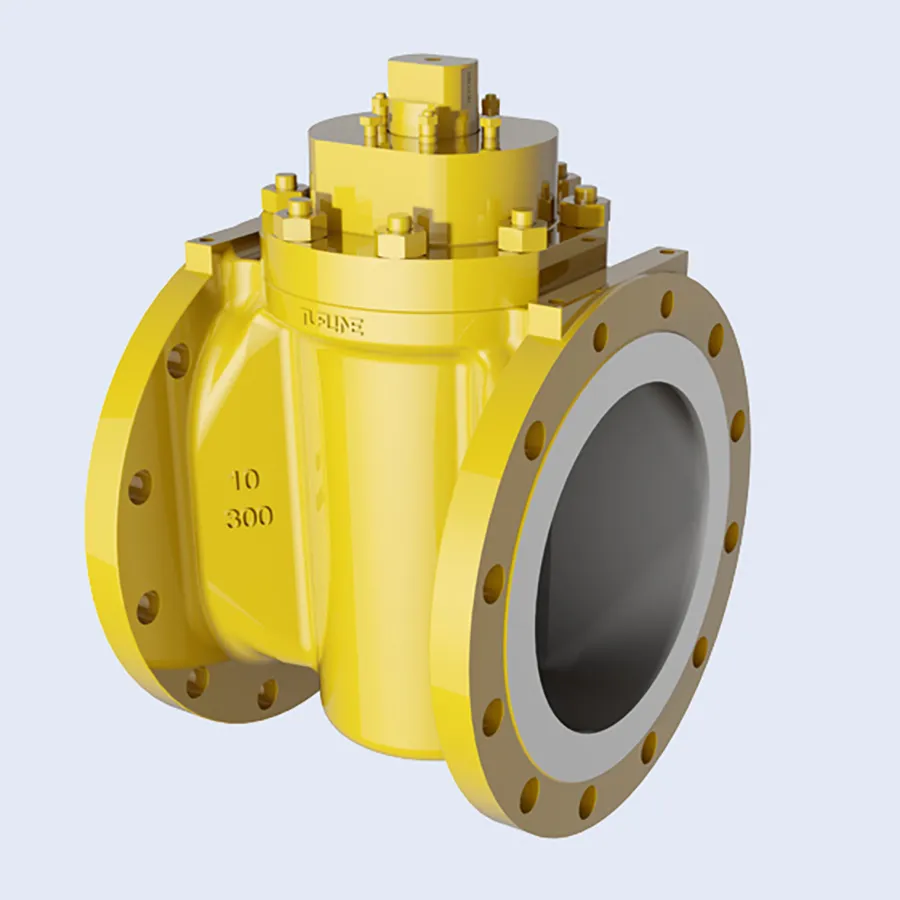

Crane Valves are designed to meet the stringent standards of highly regulated sectors. Their range includes gate, globe, check, diaphragm, and ball valves, all engineered to manage aggressive fluids, high pressures, and elevated temperatures. These valves play essential roles in safeguarding operations in facilities where failure isn’t an option.

Applications include isolating corrosive chemicals, preventing backflow in complex systems, and ensuring safe shut-off in high-purity environments.

Engineered for Safety and Compliance

Each Valve is manufactured with compliance in mind. Materials and designs are selected to meet global standards including ASME, API, and ISO. This focus on engineering quality makes them ideal for GMP-compliant pharmaceutical plants or hazardous chemical facilities where documentation and performance traceability are critical.

Valve bodies, internals, and seals are matched to their service environment, ensuring long service life and consistent sealing performance under variable loads.

Precision in Design and Application

Crane Valves are more than standard components — they’re precision-engineered to fit the exact performance requirements of your process. Options include custom trims, extended bonnets for cryogenic service, and metal-seated designs for abrasive or slurry media. Their compact form factors and modular accessories make them suitable for both new installations and tight retrofit spaces.

As a result, system designers can optimise process control without compromise, while plant operators benefit from enhanced reliability and simplified maintenance routines.

Superior Materials and Long-Term Value

Crane Valves are manufactured from materials that resist corrosion, erosion, and contamination. Whether the requirement is for high-grade stainless steel, PTFE linings, or exotic alloys, these components are built for extreme durability. Many designs feature live-loaded packing, blowout-proof stems, and fire-safe certifications for added safety assurance.

This robust build quality reduces lifecycle costs and extends operational uptime, delivering long-term value even in continuous-use environments.

Expert Support and Global Reach

Crane supports its valve range with technical expertise, application engineering, and global service infrastructure. Whether you’re selecting products for a new plant or upgrading legacy equipment, specialists can guide you to the ideal valve solution. Their commitment to product availability and aftersales support helps ensure smooth installation and continued reliability.

With manufacturing and support locations across major markets, Crane provides responsive delivery and servicing wherever operations demand it.

Wide-Ranging Applications

From chemical reactors and solvent lines to purified water systems and high-pressure refining circuits, they operate reliably in a broad range of conditions. Their adaptability and consistent performance have earned them a leading reputation with EPC firms, OEMs, and plant managers alike.

With valves designed for steam, acids, high-viscosity media, and volatile gases, they offer tailored control across virtually any industrial fluid handling challenge.

Crane and Tomlinson Hall

Tomlinson Hall is proud to supply Crane Valves to customers in need of proven, precision-engineered flow control. From cleanroom applications to chemical containment systems, our team is ready to help you specify the perfect solution. Get in touch with us today for expert support and competitive supply options.