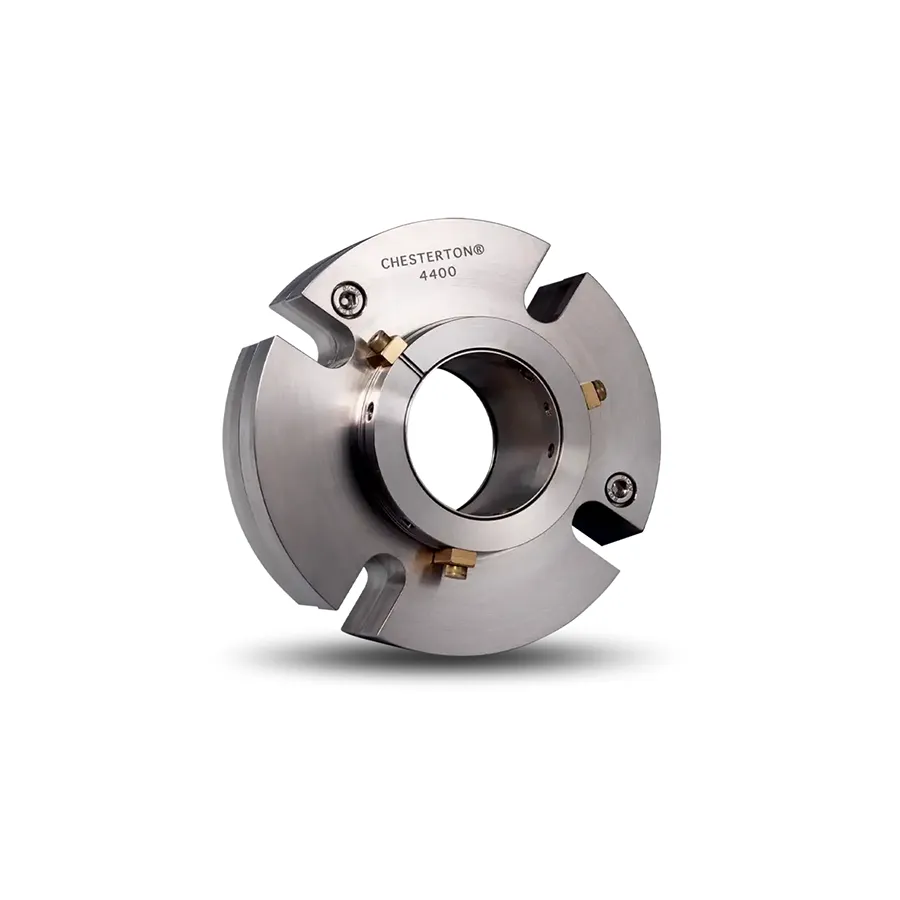

Chesterton Mechanical Seals

Chesterton Mechanical Seals are engineered to enhance equipment reliability, minimise unplanned downtime, and reduce total cost of ownership. Trusted by industries worldwide, Chesterton combines decades of experience with cutting-edge design to deliver mechanical sealing solutions that meet the highest standards of performance and durability.

Versatile Sealing for Complex Challenges

From aggressive chemical processes to demanding slurry applications, Chesterton Mechanical Seals are designed to perform in tough environments. Whether you require single, double, split, or cartridge seal configurations, their product range offers flexible options for pumps, mixers, agitators, and other rotating machinery.

Each seal is carefully engineered to suit specific operating conditions, such as pressure, temperature, and media type. This results in improved process stability, longer equipment life, and reduced maintenance frequency—critical benefits for high-output industries.

Custom Solutions with Proven Reliability

With more than 140 years of innovation behind them, Chesterton is a global leader in the sealing industry. Their mechanical seals are widely used in industries including oil and gas, water and wastewater, food and beverage, mining, and pulp and paper.

Chesterton works closely with customers to develop sealing solutions that not only meet, but exceed performance and compliance expectations. Their engineering team applies deep application knowledge to ensure compatibility with process conditions, helping clients achieve measurable improvements in efficiency.

Engineered to Reduce Downtime

Downtime is costly. Chesterton Mechanical Seals are specifically designed to make maintenance easier and quicker. Their split seals, for example, allow installation without dismantling heavy equipment—cutting downtime by up to 50% and reducing labour costs.

Their advanced cartridge seals come pre-assembled and factory-tested for ease of installation and consistent sealing performance, making them ideal for critical process lines where reliability is non-negotiable.

Sealing Technology Backed by Support

Chesterton doesn’t just provide products—they deliver comprehensive sealing strategies. Their global service teams offer application support, equipment audits, failure analysis, and training to help customers optimise seal performance and extend mean time between failures (MTBF).

This hands-on service is supported by a network of regional hubs and authorised distributors, ensuring fast access to both technical expertise and replacement parts when needed.

Focus on Efficiency and Sustainability

In today’s industrial environment, energy efficiency and emissions control are essential. Chesterton Mechanical Seals help reduce fluid and gas leakage, enabling operations to meet environmental standards while maintaining productivity. Their sealing systems also help conserve water and reduce power consumption in pumping systems.

By improving containment and reducing wear, these seals contribute to more sustainable, cost-effective plant operation. This supports organisations in meeting regulatory goals and internal sustainability targets.

Global Reach with Local Insight

With operations in over 110 countries, Chesterton combines international scale with local responsiveness. Their engineers understand regional compliance requirements and industry-specific challenges, helping customers navigate technical, regulatory, and environmental demands.

Whether it’s an emergency seal replacement or a new system specification, Chesterton delivers timely, informed support across all sectors and geographies.

Chesterton and Tomlinson Hall

Tomlinson Hall is proud to supply Chesterton Mechanical Seals, giving our customers access to advanced sealing technologies and field-proven reliability. Our team works closely with yours to specify the right solution for each application. Get in touch to discuss how we can help reduce downtime, improve efficiency, and ensure long-term sealing performance.